Apagen’s Production Management Software (APMS)

From Raw Material Purchase to Finished Goods, Fully Planned, Fully Controlled

Apagen’s Production Management Software is a ready-to-use, integrated solution designed to help manufacturing businesses manage their complete production lifecycle in one connected system.

This solution brings together Purchase, Inventory, Manufacturing, Quality Control (QC), and

Maintenance into a single platform, ensuring smooth coordination between planning, shop

floor, quality, and maintenance teams without relying on spreadsheets, emails, or

disconnected tools.

Purchase

Control production-driven purchasing with complete visibility

Inventory

Maintain real-time visibility of raw materials, WIP, and finished goods

Manufacturing

Plan, execute, and track production with full shop floor visibility

Maintenance

Keep machines running and prevent unplanned production downtime

Quality Control (QC)

Maintain consistent product quality at every stage of production

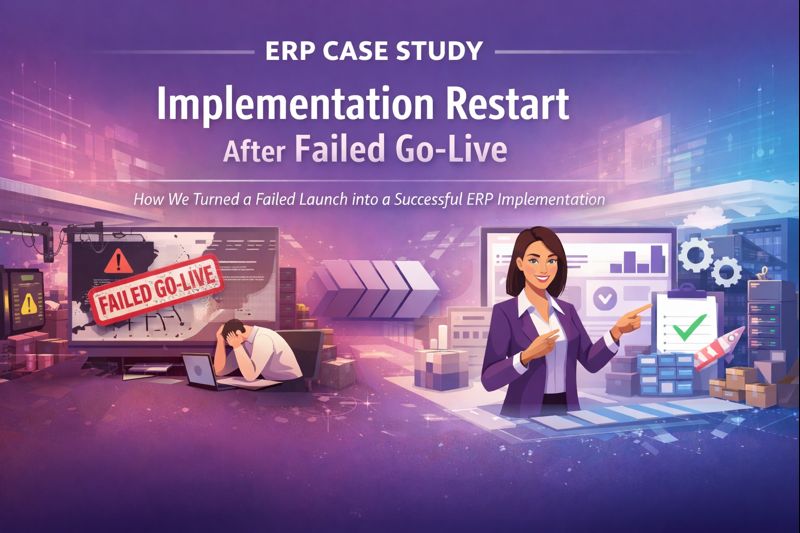

Implementation Restart After Failed Go Live

Stabilizing ERP rollout and correcting execution gaps.

Vendor Lock In Resolution

Project takeover with full knowledge transfer.

Performance and Stability Recovery

Fixing live ERP performance and system reliability.

Performance and Stability Recovery

Fixing live ERP performance and system reliability.

FAQs:

What problems does this production management software solve?

Apagen’s Production Management Software eliminates disconnected systems, manual production tracking, and material shortages. It connects purchasing, inventory, manufacturing, quality, and maintenance into one system, giving manufacturers complete operational control and visibility.

Who should use this solution?

This solution is ideal for manufacturing companies, OEMs, EPC firms, and industrial manufacturers managing complex production processes, multiple materials, and shop floor

operations.

Can the system be customized to our production process?

Yes. While the software comes with proven, ready-to-use workflows, it can be configured and customized based on your BoMs, routing, quality standards, and maintenance practices.

How long does implementation usually take?

Implementation timelines depend on production complexity and module scope. Most small to mid-sized manufacturers can go live within a few weeks, including configuration, testing, and user training.

Do you provide training and post-implementation support?

Yes. Apagen provides user training, documentation, go-live assistance, and ongoing support to ensure smooth adoption and continuous improvement of production operations.