Reading Time: 20 minutes | Last Updated: February 2026

Discover how a procurement management system transforms manufacturing operations by providing real-time inventory visibility, automated vendor management, and streamlined billing processes. Learn implementation strategies and best practices from industry experts.

In today’s competitive manufacturing landscape, implementing an Odoo procurement management system, success isn’t solely determined by sales volume. The foundation of profitability lies in strategic procurement-buying the right materials, at the right time, at the right price. Yet, many manufacturers continue to struggle with outdated procurement processes that drain resources and create operational bottlenecks.

This comprehensive guide explores how implementing a robust procurement management system can revolutionize your manufacturing operations, based on real-world applications and proven methodologies.

The Hidden Cost of Manual Procurement in Manufacturing

Before exploring solutions, it’s crucial to understand the challenges that plague traditional procurement processes. Manual procurement systems create a domino effect of inefficiencies that impact every aspect of manufacturing operations.

Lack of Real-Time Inventory Visibility

Without a centralized procurement management system, manufacturers operate in the dark regarding their actual inventory levels. This blind spot leads to over-purchasing, tying up valuable capital in excess stock. When your team can’t see what’s available in real-time, they make purchasing decisions based on assumptions rather than data, resulting in unnecessary expenditure and warehouse overcrowding.

Inefficient Vendor Communication

Managing vendor relationships through fragmented channels-phone calls, emails, and WhatsApp messages-creates chaos. Important pricing information gets lost in email threads, delivery confirmations disappear in message histories, and there’s no single source of truth for vendor performance. This scattered approach wastes time and creates opportunities for miscommunication and errors.

Manual Billing and Payment Tracking Nightmares

Finance teams face constant struggles when procurement lacks automation. Manual purchase bill entry is time-consuming and error-prone. Tracking payment due dates across multiple vendors requires constant vigilance, and without proper systems, overdue payments accumulate, potentially incurring penalties and damaging vendor relationships. The administrative burden alone drains productivity that could be directed toward strategic financial management.

What Is a Procurement Management System?

A procurement management system is a comprehensive software solution designed to digitize, streamline, and optimize the entire procurement lifecycle within an organization. Unlike basic inventory tracking or standalone accounting software, a modern procurement management system integrates seamlessly with your enterprise resource planning (ERP) infrastructure to provide end-to-end visibility and control.

At its core, this system transforms procurement from a reactive, manual process into a proactive, data-driven operation. It serves as the central nervous system for all purchasing activities, connecting inventory management, vendor relationships, financial transactions, and production planning into a cohesive ecosystem.

Key Components of an Effective Procurement Management System

- Real-time inventory tracking and stock level monitoring – Know exactly what you have, where it is, and when to reorder

- Centralized vendor management database – Maintain complete vendor profiles including contact details, pricing history, and performance metrics

- Automated purchase order generation – Create POs with pre-populated vendor information and historical pricing

- Integrated billing and payment tracking – Automatically match bills to purchase orders and track payment due dates

- Comprehensive reporting and analytics – Generate insights on spending patterns, vendor performance, and procurement efficiency

Core Features That Drive Procurement Excellence

1. Real-Time Inventory Visibility and Stock Management

The foundation of effective procurement is knowing exactly what you have. Modern Odoo procurement management systems provide instant visibility into your inventory across all locations and warehouses.

When you view any product in the system, you immediately see:

- Current stock on hand across all warehouses

- Time to replenishment based on usage patterns

- Current inventory value using your preferred costing method (FIFO, average cost, etc.)

- Reserved quantities for existing orders

- Quantities that need to be ordered to maintain optimal stock levels

This comprehensive view eliminates panic buying and prevents production stoppages. Your procurement team makes informed decisions based on actual data, not guesswork. The system automatically alerts you when stock levels approach reorder points, ensuring you maintain optimal inventory without over-investing in raw materials.

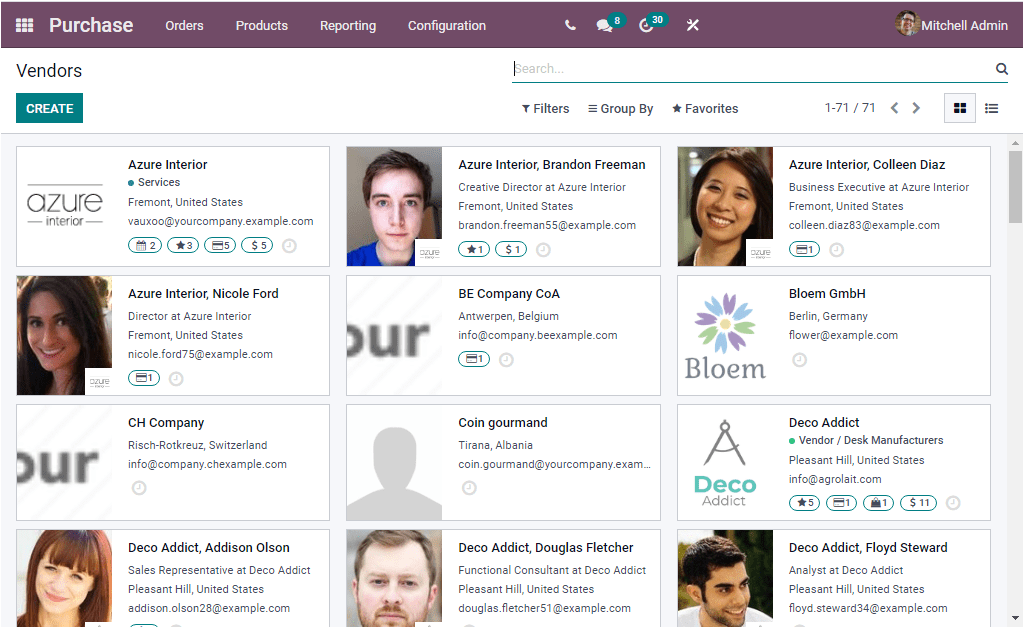

2. Intelligent Vendor Management and Performance Tracking

A sophisticated Odoo procurement management system transforms vendor relationships from scattered communications into structured partnerships. Every vendor in your system has a comprehensive profile that serves as a single source of truth.

Vendor Management Capabilities:

- Complete contact information and communication history – Never lose important vendor details in email threads

- Full purchase history – Review all past transactions, orders, and deliveries at a glance

- Product catalog and pricing – See all products supplied by each vendor with historical pricing trends

- Delivery performance metrics – Track on-time delivery rates to identify reliable suppliers

- Price lists with validity periods – Maintain negotiated pricing and discount structures

- Lead time tracking – Know exactly how many days each vendor needs to deliver specific products

The system maintains price consistency by automatically fetching the latest negotiated prices when you create purchase orders. If you’ve ordered a product from a vendor before, the system pre-populates the pricing, eliminating manual lookup and preventing pricing errors. You can also track vendor performance through metrics like on-time delivery rates, helping you make data-driven decisions about which suppliers to prioritize for critical materials.

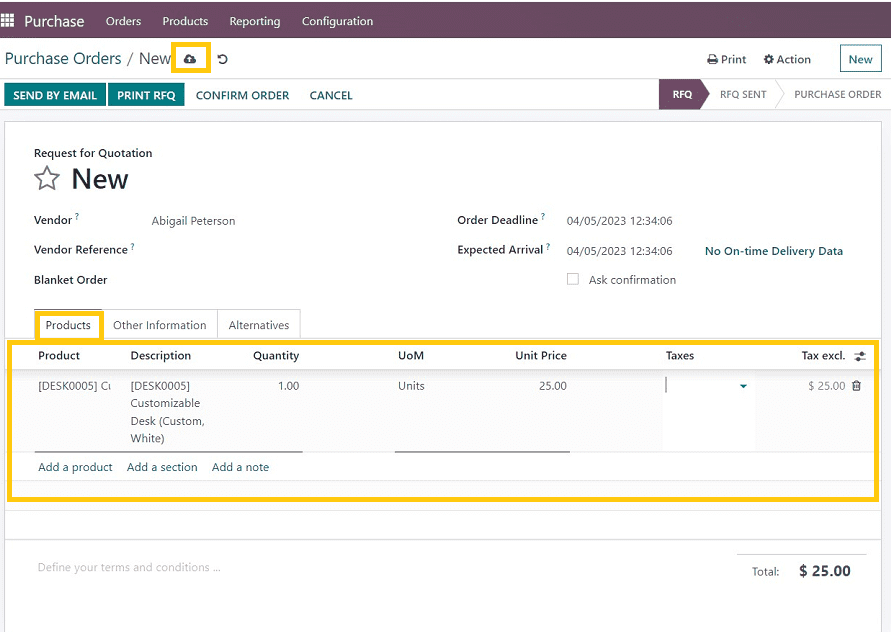

3. Automated Purchase Order Processing

Creating purchase orders becomes remarkably efficient when your Odoo procurement management system maintains complete vendor and product histories. The automation eliminates repetitive data entry while ensuring accuracy and consistency.

When creating a purchase order:

- Select your vendor and the system automatically populates their contact details and payment terms

- Choose products previously ordered from this vendor, and pricing automatically populates from price lists or previous orders

- The system applies the correct fiscal position and currency based on vendor location

- Expected arrival dates calculate automatically based on the vendor’s historical delivery performance and lead times

- Lead times can be customized per product and vendor, ensuring accurate delivery forecasting

This intelligent automation ensures pricing consistency across orders, prevents manual entry errors, and provides accurate delivery forecasts for production planning. Your procurement team spends less time on paperwork and more time on strategic vendor negotiations and relationship building.

4. Seamless Inventory Receipt and Stock Updates

The true power of an integrated Odoo procurement management system becomes evident when materials arrive. The receiving process connects seamlessly to both inventory management and production planning, creating real-time visibility across your entire organization.

The receipt process works as follows:

- When materials arrive, warehouse staff access the pending receipts through the inventory module

- The system displays expected delivery dates and product details from the original purchase order

- Upon validation, the system automatically generates delivery challans (receipt documents)

- Stock levels update in real-time across all connected systems

- Production departments immediately see the updated inventory availability

- Inventory valuation updates based on your chosen costing method (average cost, FIFO, etc.)

This eliminates the lag time between physical receipt and system updates. No manual stock entries are required, reducing errors and ensuring that production planning always works with accurate, real-time inventory data. The system maintains complete traceability through lot numbers and serial numbers when needed, critical for industries with stringent quality control requirements.

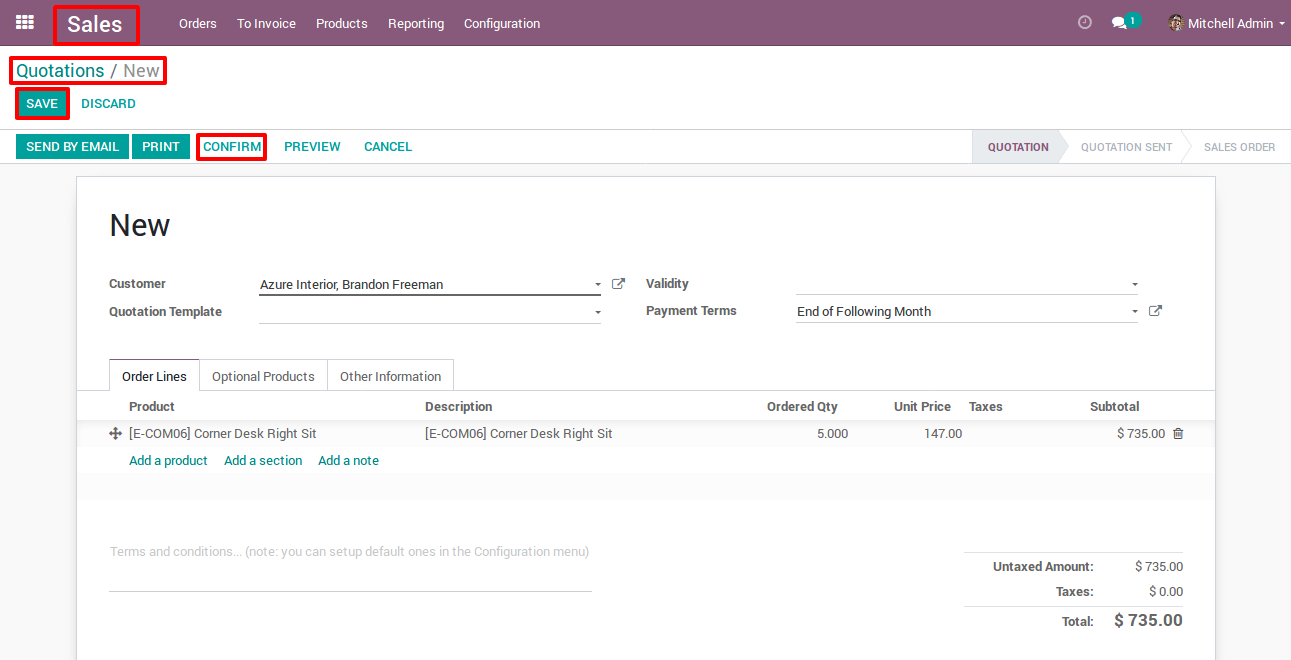

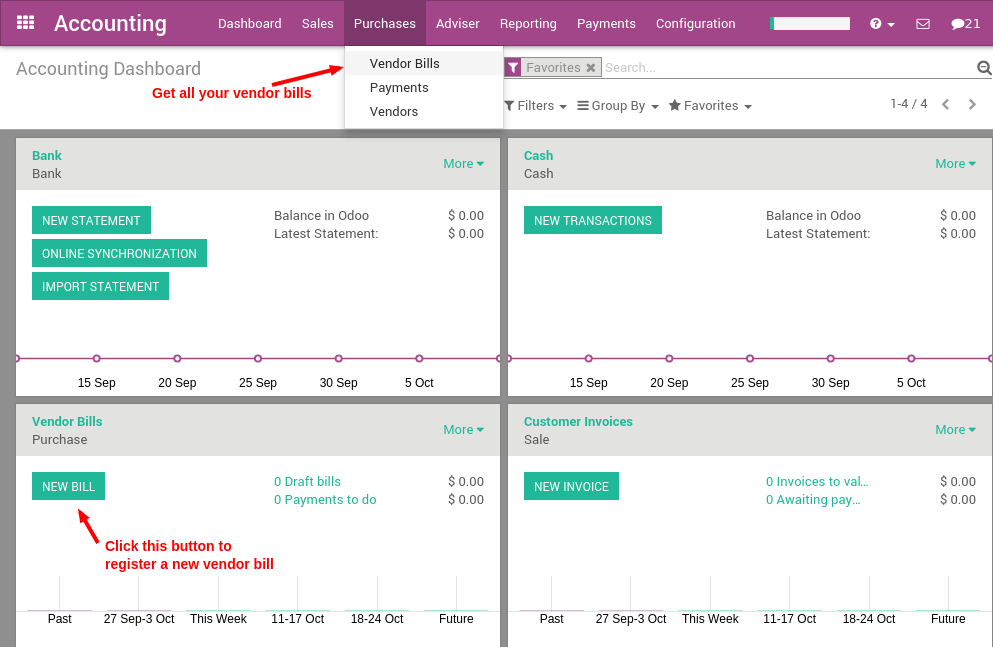

5. Integrated Billing and Payment Management

Perhaps the most significant time-saver for finance teams is the seamless integration provided by Odoo procurement management system between procurement and accounting. The procurement management system creates a direct connection from goods receipt to bill registration to payment tracking, eliminating manual data entry and preventing errors.

How integrated billing works:

- After receiving goods, procurement teams upload vendor bills directly in the system

- Bills automatically link to the corresponding purchase order and receipt

- The system performs three-way matching: purchase order, goods receipt, and invoice

- Supporting documents attach directly to the bill for audit trails

- Finance teams review and verify bills before posting to accounting books

- Once posted, bills automatically appear in accounts payable with due dates tracked

This integration ensures perfect matching between quantities received and quantities billed, eliminating quantity discrepancies and pricing errors. Finance teams can instantly see all outstanding payments, filter by due dates, and identify overdue invoices before they incur penalties.

The system provides complete visibility into cash flow commitments, allowing for more effective working capital management. You can filter vendor bills by payment status, due date, or specific vendors, enabling strategic payment scheduling and maintaining healthy vendor relationships through timely payments.

6. Comprehensive Reporting and Analytics

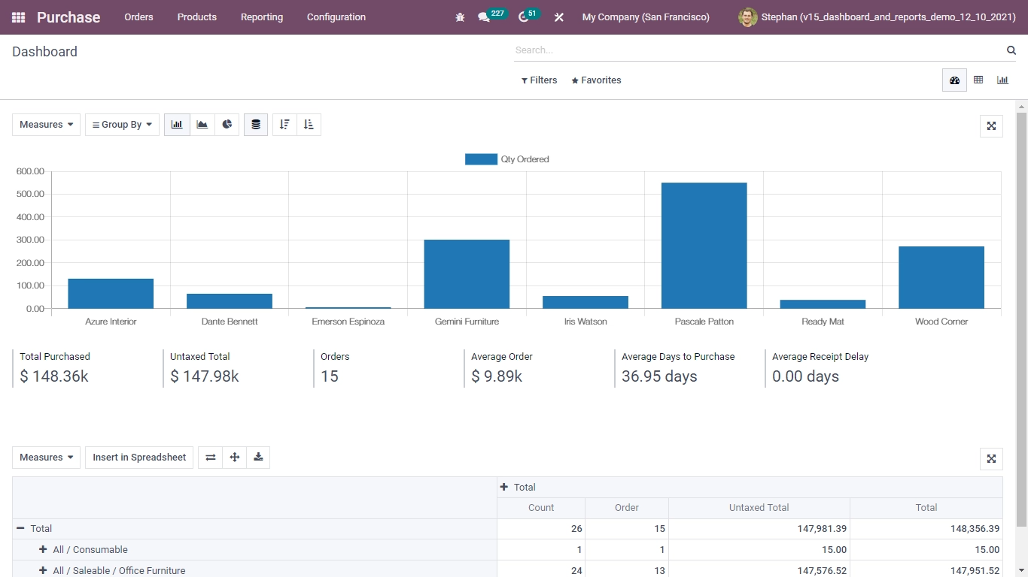

Management visibility is essential for strategic decision-making. A robust Odoo procurement management system provides comprehensive reporting across the entire procurement lifecycle, from initial requisition to final payment.

Key reporting capabilities include:

- Purchase reporting – Analyze total purchased value, number of orders, supplier service levels, on-time delivery rates, and top vendors by spend

- Stock level reporting – Monitor inventory levels, turnover rates, and identify slow-moving or obsolete stock

- Accounting reports – Track accounts payable, vendor ledgers, aging reports, and cash flow commitments

- Invoice analysis – Examine spending patterns, identify cost-saving opportunities, and validate pricing consistency

- Dashboard metrics – View real-time KPIs including purchase trends, vendor performance, payment status, and budget utilization

These reports transform raw transactional data into actionable insights. Management can identify underperforming vendors, negotiate better terms with high-volume suppliers, optimize inventory levels to reduce carrying costs, and ensure cash flow aligns with operational requirements. The dashboard provides an at-a-glance view of procurement health, making it easy to spot trends and address issues before they impact production.

Real Business Impact: Measurable Benefits of Implementation

Implementing a procurement management system delivers tangible, measurable improvements across multiple dimensions of manufacturing operations. Organizations that transition from manual to automated procurement consistently report significant benefits.

Reduced Capital Tied in Inventory

Real-time visibility eliminates over-purchasing driven by uncertainty. When procurement teams can see actual stock levels, reserved quantities, and consumption patterns, they purchase only what’s needed. This optimization can reduce inventory carrying costs by 20-30%, freeing up working capital for strategic investments.

Improved Vendor Relationships and Pricing

Systematic vendor management leads to better negotiations and stronger partnerships. When you track delivery performance, maintain pricing history, and consolidate purchases with reliable suppliers, you gain negotiating leverage. Organizations report achieving 5-15% cost reductions through better vendor management and strategic sourcing enabled by system insights.

Eliminated Production Delays

Real-time inventory visibility and automated reorder alerts prevent stockouts that halt production. The system ensures materials arrive when needed, maintaining production schedules and meeting customer delivery commitments. This reliability directly impacts customer satisfaction and revenue.

Enhanced Financial Accuracy and Compliance

Automated three-way matching between purchase orders, receipts, and invoices virtually eliminates billing errors. Finance teams report 90%+ reduction in discrepancies and payment errors. Timely payment tracking prevents late fees and early payment discounts become feasible when cash flow is predictable.

Increased Productivity Across Departments

Procurement teams spend less time on administrative tasks and more time on strategic activities like vendor negotiations and process improvement. Finance teams reduce time spent on bill entry and payment tracking by 60-70%. Production planners make better decisions with reliable inventory data, reducing expediting costs and inefficiencies.

Implementation Best Practices for Maximum ROI

Successful implementation of an Odoo procurement management system requires careful planning and execution. Organizations that follow structured approaches achieve faster adoption and realize benefits more quickly.

Start with Data Foundation

Before going live, invest time in cleaning and importing master data. Accurate product information, vendor details, and opening stock levels are critical. Poor data quality undermines system effectiveness, while clean master data enables immediate benefits from day one.

Phase the Rollout

Consider starting with one product category or one warehouse before full deployment. This phased approach allows teams to learn the system, identify process refinements, and build confidence before scaling across the entire organization.

Train Comprehensively Across Functions

Procurement, warehouse, finance, and production teams all interact with the system differently. Role-specific training ensures each department understands how to use the system effectively for their workflows. Include hands-on practice with realistic scenarios.

Establish Clear Processes and Ownership

Define who is responsible for vendor management, purchase order approval, goods receipt, bill verification, and data maintenance. Clear ownership prevents gaps in execution and ensures accountability. Document standard operating procedures for common workflows.

Monitor and Optimize Continuously

Use the system’s reporting capabilities to track adoption and identify bottlenecks. Review vendor performance metrics quarterly and adjust supplier relationships accordingly. Regularly assess whether reorder points and lead times accurately reflect reality and refine them based on actual data.

Choosing the Right Procurement Management System

Not all procurement management systems are created equal. Odoo procurement management system stands out as a comprehensive, integrated solution. When evaluating solutions, consider these critical factors that determine long-term success.

Integration Capabilities

The Odoo procurement management system integrates seamlessly with existing ERP modules, accounting software, and production planning tools. Standalone procurement systems that don’t connect to other business systems create data silos and require duplicate entry. Look for solutions that provide native integration with your current technology stack or robust APIs for custom integration.

Scalability and Flexibility

Choose a system that can grow with your business. Can it handle multiple warehouses, currencies, and business units? Does it support your industry-specific requirements like lot tracking, serial number management, or compliance documentation? Ensure the system is configurable to match your unique workflows rather than forcing you to change proven processes.

User Experience and Adoption

The best system is worthless if your team won’t use it. Evaluate the user interface for intuitiveness. Can warehouse staff quickly process receipts on mobile devices? Can procurement teams create purchase orders in minutes rather than hours? User adoption determines ROI, so prioritize systems that reduce complexity rather than add it.

Vendor Support and Community

Implementation and ongoing support are critical. Does the vendor provide training, documentation, and responsive technical support? Is there an active user community that shares best practices? Consider the vendor’s track record in your industry and their commitment to product development and updates.

Cost Structure and Total Cost of Ownership

Look beyond initial licensing costs to understand total cost of ownership. Factor in implementation costs, training, customization, ongoing support fees, and infrastructure requirements. Cloud-based solutions typically offer lower upfront costs and predictable monthly expenses, while on-premise systems may provide greater control for organizations with existing IT infrastructure.

Industry-Specific Applications

Odoo procurement management systems deliver value across diverse manufacturing sectors, though implementation priorities may vary by industry.

Discrete Manufacturing (Electronics, Automotive, Machinery)

These industries benefit enormously from bill of materials integration and component tracking. Serial number management enables warranty tracking and quality control. Multiple supplier management for identical components allows for supply chain resilience and competitive pricing through strategic sourcing.

Process Manufacturing (Food, Pharmaceuticals, Chemicals)

Lot traceability is critical for compliance and recall management. The system must track raw material lots through production to finished goods. Expiry date management prevents usage of expired materials, while quality certificates and compliance documentation storage meet regulatory requirements.

Fabrication and Job Shop Manufacturing

Project-based procurement tied to specific customer orders is essential. Material requisitions from production drive purchasing, ensuring materials arrive aligned with project schedules. Vendor-managed inventory for high-volume items reduces administrative overhead while maintaining availability.

High-Mix, Low-Volume Manufacturing

These manufacturers need exceptional flexibility in vendor and product management. The ability to quickly add new suppliers and parts numbers without system bottlenecks is critical. Supplier performance tracking helps identify which vendors can reliably deliver specialty components with short lead times.

The Future of Procurement Management: Emerging Trends

Odoo procurement management systems continue to evolve, incorporating advanced technologies that further enhance efficiency and decision-making capabilities.

AI-Powered Demand Forecasting

Machine learning algorithms analyze historical consumption patterns, seasonal trends, and external factors to predict future demand more accurately than traditional methods. These predictions enable proactive procurement, reducing both stockouts and excess inventory.

Supplier Risk Management and Alternative Sourcing

Advanced systems monitor supplier financial health, geopolitical risks, and supply chain disruptions. Automated alerts notify procurement teams of potential issues before they impact operations, allowing time to activate alternative suppliers or increase safety stock for critical materials.

IoT Integration and Automated Reordering

Smart sensors on bins and storage areas automatically update inventory levels without manual counting. When stock reaches reorder points, the system can automatically generate purchase requisitions or even place orders with approved vendors, creating a truly hands-free procurement process for routine materials.

Blockchain for Supply Chain Transparency

Blockchain technology enables unprecedented traceability in supply chains, particularly valuable for industries requiring provenance verification. Every transaction from raw material sourcing through manufacturing to delivery becomes immutably recorded, supporting compliance, sustainability initiatives, and quality assurance.

Sustainability and ESG Tracking

Modern procurement systems increasingly incorporate environmental, social, and governance metrics. Track supplier sustainability certifications, carbon footprint of materials, and ethical sourcing compliance. These capabilities support corporate sustainability goals while meeting increasing customer and regulatory expectations.

Conclusion: Transform Procurement from Cost Center to Strategic Advantage

Manufacturing success depends on controlled, efficient procurement. While sales drive revenue, procurement protects profitability by ensuring materials arrive at the right time, at the right price, and in the right quantities.

A robust Odoo procurement management system transforms procurement from a reactive, manual process plagued by inefficiencies into a proactive, strategic function that drives competitive advantage. Real-time inventory visibility prevents both stockouts and excess inventory. Intelligent vendor management strengthens supplier relationships while ensuring pricing consistency. Automated workflows free your team from administrative drudgery, allowing them to focus on strategic initiatives.

The integrated nature of modern procurement systems-connecting inventory, purchasing, receiving, and accounting-eliminates data silos and manual reconciliation. Information flows seamlessly across departments, providing management with real-time visibility into procurement performance, cash flow commitments, and supplier reliability.

For manufacturers still relying on manual procurement processes-juggling spreadsheets, phone calls, and email chains-the path forward is clear. Implementing a procurement management system isn’t just about efficiency; it’s about building a foundation for sustainable growth, financial control, and operational excellence. The question isn’t whether to implement such a system, but how quickly you can realize the benefits that your competitors may already be enjoying.

Frequently Asked Questions About Procurement Management Systems

What is a procurement management system and why do I need one?

A procurement management system is an integrated software solution that digitizes and automates the entire procurement lifecycle-from identifying material needs through vendor selection, purchase order creation, goods receipt, and payment processing. Manufacturers need this system because manual procurement creates blind spots in inventory visibility, wastes time on repetitive tasks, leads to over-purchasing that ties up capital, creates pricing inconsistencies across orders, and makes it difficult to track vendor performance. The system brings structure, control, and real-time visibility to procurement, transforming it from a cost center into a strategic advantage.

How does a procurement management system integrate with existing ERP systems?

Modern procurement management systems are typically either built into comprehensive ERP platforms or designed to integrate seamlessly with existing ERP systems through APIs and standardized data exchange protocols. Integration connects procurement data with inventory management, production planning, accounting, and financial reporting modules. This creates a unified information flow where purchase orders automatically update inventory forecasts, goods receipts immediately reflect in production availability, and vendor bills post directly to accounts payable without manual entry. When evaluating systems, verify that they can integrate with your specific ERP platform, whether SAP, Oracle, Microsoft Dynamics, Odoo, or other solutions.

What features should I prioritize when selecting a procurement management system?

Prioritize these core capabilities: real-time inventory visibility showing current stock, reserved quantities, and reorder requirements; comprehensive vendor management including contact details, pricing history, delivery performance, and product catalogs; automated purchase order generation with pricing and lead time auto-population; seamless receiving processes that update inventory and production availability instantly; integrated billing with three-way matching between POs, receipts, and invoices; robust reporting across procurement, inventory, and financial dimensions; and mobile accessibility for warehouse teams processing receipts. Beyond these fundamentals, consider industry-specific requirements like lot traceability for pharmaceuticals, serial number tracking for electronics, or project-based procurement for job shops.

How long does it take to implement a procurement management system?

Implementation timelines vary based on organization size, process complexity, and data quality. Small to mid-sized manufacturers with straightforward processes can typically implement cloud-based systems in 4-12 weeks. This includes data migration, system configuration, user training, and phased rollout. Larger organizations with multiple locations, complex approval workflows, or extensive customization requirements may need 3-6 months for comprehensive deployment. The critical success factor is data preparation-clean vendor lists, accurate product catalogs, and verified opening stock levels. Organizations that invest time upfront in data quality achieve faster implementation and realize benefits immediately upon go-live.

What is the typical ROI of implementing an Odoo procurement management system?

Most manufacturers achieve payback within 12-18 months through multiple value streams. Reduced inventory carrying costs (20-30% reduction in excess stock) free up significant working capital. Better vendor management and strategic sourcing typically yield 5-15% procurement cost savings. Elimination of billing errors and duplicate payments prevents financial leakage. Time savings are substantial-procurement teams spend 60% less time on administrative tasks, finance teams reduce bill processing time by 70%, and production planning improves with reliable inventory data. Beyond quantifiable savings, improved vendor relationships, eliminated production delays, and better cash flow management create strategic value that compounds over time.

Can a procurement management system handle multiple currencies and international vendors?

Yes, robust procurement management systems support multi-currency transactions and international vendor management. The system maintains vendor profiles with their local currency, automatically applies appropriate fiscal positions based on vendor location, handles currency conversion for reporting and financial consolidation, and manages country-specific tax requirements and compliance documentation. When creating purchase orders, the system uses the vendor’s currency for transactions while providing visibility in your base currency for financial planning. Exchange rate management capabilities ensure accurate valuation of purchases and payables across currencies.

How does vendor performance tracking work in a procurement management system?

The system automatically tracks key vendor performance metrics based on actual transaction data. On-time delivery rates calculate the percentage of orders delivered by the promised date versus late deliveries. Lead time accuracy compares committed delivery times against actual receipt dates. Quality metrics can incorporate inspection results and rejection rates. Pricing consistency tracks whether vendors honor quoted prices or introduce unexpected charges. The system aggregates this data into vendor scorecards accessible during purchasing decisions, enabling data-driven supplier selection. Regular performance review reports help identify top-performing vendors deserving increased business and problematic suppliers requiring corrective action or replacement.

What security measures should a procurement management system include?

Enterprise-grade security is essential given the financial and operational sensitivity of procurement data. Look for role-based access control ensuring users only see and edit information relevant to their responsibilities. Approval workflows prevent unauthorized purchases beyond defined limits. Audit trails log all transactions, modifications, and access for compliance and fraud prevention. Data encryption protects information in transit and at rest. Regular automated backups prevent data loss. For cloud-based systems, verify SOC 2 Type II compliance, data center security certifications, and disaster recovery capabilities. Multi-factor authentication adds an essential security layer for system access.

How does three-way matching work and why is it important?

Three-way matching is an automated verification process that compares three critical documents: the purchase order (what you intended to buy), the goods receipt (what you actually received), and the vendor invoice (what the vendor is charging you). The procurement management system automatically matches quantities and prices across these documents, flagging any discrepancies for review. This prevents common errors like paying for goods never received, processing invoices for quantities exceeding what was delivered, or paying prices higher than quoted in the purchase order. The automation eliminates manual reconciliation, prevents duplicate payments, and ensures every payment is legitimate and accurate, protecting your organization from both honest mistakes and fraudulent billing.

Can small and medium-sized manufacturers benefit from procurement management systems?

Absolutely. While procurement management systems were historically enterprise software requiring significant investment, modern cloud-based solutions offer affordable, scalable options for manufacturers of all sizes. Small and medium manufacturers often benefit even more dramatically than large enterprises because they’re transitioning from entirely manual processes. The efficiency gains, error reduction, and working capital optimization deliver disproportionate impact when resources are limited. Cloud-based systems eliminate infrastructure costs and provide predictable monthly expenses. Start with core modules and expand functionality as your needs grow. Many SMEs report that procurement automation frees up personnel to focus on growth initiatives rather than administrative tasks, making the system a growth enabler rather than just an efficiency tool.

Ready to Transform Your Procurement Operations?

If you’re ready to eliminate manual procurement inefficiencies and unlock the strategic value of automated procurement management, we’re here to help. Our team specializes in implementing tailored procurement solutions for manufacturers across diverse industries.

We offer:

- Free consultation to assess your current procurement challenges

- Custom demonstrations tailored to your industry and specific requirements

- Implementation planning and ROI analysis

- Ongoing support and optimization services

Contact us today to schedule your personalized demonstration and discover how a procurement management system can transform your manufacturing operations. Don’t let manual procurement processes continue to drain profitability and limit your growth potential.

About the Author

This guide is based on extensive experience implementing procurement management systems for manufacturers across industries. Our team has helped dozens of organizations transition from manual procurement to automated, integrated solutions, witnessing firsthand the transformative impact on operations, profitability, and competitive positioning. The insights shared here reflect real-world implementation experience, user feedback, and measurable results achieved by manufacturers who have embraced modern procurement technology.