Plastic Mold Manufacturing Optimized with Cost Effective Solution

Today, we are going to see how at Apagen we have created a cost effective solution that is tailored for the plastic mold manufacturing companies that are having a low budget and want to move to ERP for refining their day to day operations.

Well, one of our clients is having a small plastic mold manufacturing company that is situated in the heart of Bhawana industrial area in north Delhi, India.

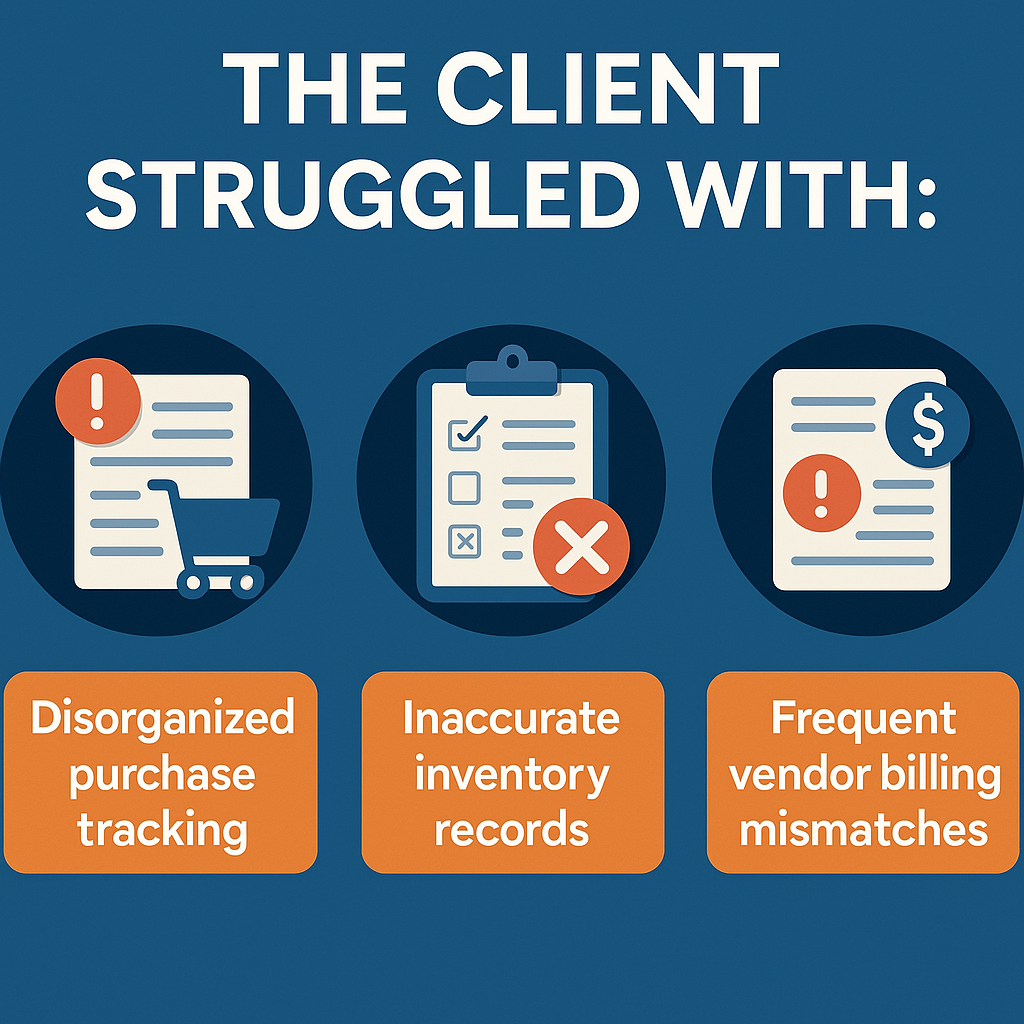

The client had noticed a lot of issues within their backend operations that includes – disorganized purchase tracking, inaccurate inventory records, and vendor billing frequent mismatches which has led to problems in their day to day operations.

- They were not having any system at hand that would be able to efficiently manage and help monitor purchase transactions within their backend along with the related financial transactions. This was leading to a whole lot of problems like – delay in payments, inaccuracy in their inventory record management and this led to what they were experiencing on ground – not able to manage budgets or make any forecasting.

- They were having mismatched and inaccurate records for their inventory which was not actually mapping with their physical stock. This was a major issue which is usually called as the inventory record inaccuracy due to which they faced problems like stockouts, overstocking, and majorly financial losses.

- Also, frequent vendor billing mismatches were leading to payment delays, strained vendor relationships, and relatable financial inaccuracies.

Manual Processes Slowed Them Down

The main reason for their frustration was that the client backend was using manual and old traditional ways to manage their operations.

- They were lacking proper methods through which they could track their purchase order and this was making them loose the respective orders.

- There was lot of times when their stock levels were not accurate which directly was leading to shortages in materials and some time making over purchases.

- Vendor billing was giving them hard time due to mismatches and delayed reconciliations.

- For their supply chain part there was no actual real time visibility to see what was happening within the same.

So, their main focus to be honest was on that they were in need of proper solution that was fast and effective but within their restricted budget and not a full fledged ERP system.

Here, comes the actual part where they were struggling and which would make the situation more challenging on our part! The said that they have a limited amount of budget that they were ready with to utilize for simplifying their business operations and they were looking out for a quick setup of the ERP system and were not interested in any complex setups.

Provided them a Tailored & In Budget Odoo Solution

We did not push them towards a costly ERP implementation and setup but rather understood what exactly was their requirement and carefully created a bundle solution that would tailor to their need using the Odoo’s modular system at hand.

Well, having said that, we understood their requirements and provided them with a budget friendly and quick setup solution that we tailored for their particular requirement. Let’s check what we implemented and customized as per the client’s tight driven deadline and budget –

Modules :

- Purchase Management

- Inventory Control

- Vendor Billing and Accounting

What was Customized:

- Simplified user workflows for a small team

- Automated three-way matching (PO → Goods Receipt → Vendor Bill)

- Real-time inventory alerts to prevent stockouts and overstocking

- Basic but effective vendor tracking dashboard

- Clear reporting for quick purchase and billing decisions

How this Tailored Solution helped the Client

The solution we provided helped the client in ways that they were actually requiring their operations to work.

Streamlined Purchasing:

- Purchase orders now created, tracked, and approved with real-time visibility.

- No more missed follow-ups or delayed orders.

Accurate Inventory Management:

- Stock levels updated instantly after every transaction.

- Clear minimum stock alerts prevent raw material shortages.

Easy Vendor Billing:

- Seamless reconciliation of purchase orders, receipts, and vendor bills.

- Reduced payment errors and faster vendor settlements.

Cost-Effective Solution:

- Delivered on time and within the client’s budget.

- Focused only on critical operations — no unnecessary add-ons.

Client Testimonial

“We thought a system like this would be out of our budget. But the tailored solution for plastic mold manufacturing not only fit our price range, it solved exactly what we were struggling with. We now have full control over our purchases, inventory, and vendor payments — all without overcomplicating our work.”

— Owner, Plastic Mold Manufacturing Company

Key Takeaways for Plastic Mold Manufacturing

With our industry tailored solutions at hand for manufacturing now there is no need for you to make overspendings so as to resolve your operational functions that involve purchase, inventory, and vendor billings. The specific bundles for your requirements will for sure will help you to gain operational excellence within your tight deadlines and deliver you with what exactly your business is in need of.

So, even if you are manufacturer who is growing or it might be that you are just looking to bring control to your daily manufacturing operations we for sure can bring in the change that you require. Depending upon your business needs we will provide you with respective tailored solutions that will work within your budget and timelines.

To know more on how we can help you streamline your plastic mold manufacturing operations in a quick and affordable way drop us a line at sales@apagen.com or call us at +91 9971800665.

No Comments

Sorry, the comment form is closed at this time.