3 Proven Ways How Odoo Cut Costs for a Plastic Injection Molding Manufacturer

We have one of our clients (SME) who is basically a plastic injection molding manufacturer based out of Delhi NCR. He is having an employee strength of around 120 along with three production lines in Patparganj and an annual turn over equivalent to 40Cr.

So, this client is like supplying molded parts to the automotive and consumer goods manufacturers PAN India as per the discussion that we had earlier regarding his client base.

And one thing came up in the discussion as we usually encounter with the SMEs that they were used to running their operations on spreadsheets and some kind of basic accounting software. Hence, operations like purchases were being made manually and they used to update their inventory once a week as per their own need and their vendor bills were piling up at the month end.

So, after all this the owner of the manufacturing unit wanted us to provide him with complete control over operations and yes there must be minimal spending, that was his priority.

Let’s Go Through their Pain Points

When we went out to check their operation on the ground within their plant we were able to grab on the bottleneck issues they were actually facing.

First of all, their purchase department was having no system at hand using which they could have compared vendor prices or track the consumptions and hence it was for sure making them over order the raw materials like resins, additives, and packaging. So the result was obvious that their working capital was staying blocked.

Secondly, we also saw inventory gaps like what i mean to say is that their store keepers were having no knowledge of what was happening to the stocks as he was not having a real time visibility. This was leading to stockouts that led to hauls in production and that too twice in a month. So, here we came to the conclusion that there was a huge variance between their physical and book stocks.

The last pain point was that their bills rarely matched with the purchase orders or receipts and hence their finance team was almost wasting 4-5 hours daily reconciling and the disputes with the vendors were delaying their payments.

For you to understand the crux their margins were already thin and their operational inefficiency was eating away their profits.

Odoo ERP Solution for Plastic Injection Molding Manufacturer

Our approach was lean what i mean with that we did not use any fancy customizations rather we provided core features of Odoo which included purchase, inventory, and vendor billing modules that we have customized over our past 16+ years of experience working to fit with the plastic injection molding manufacturer.

The purchase module has helped them in various ways like now they have automated RFQs, they can compare vendors, and have the options to track the purchase orders. We have also provided vendor scorecards that have helped them in choosing the right vendor depending on the delivery time and quality.

For the inventory module we had implemented barcode scanning along with batch tracking and warehouse workflows which now allows them to have stock movement which is now real-time and not weekly as they used to do before the Odoo ERP solution implementation.

We had also implemented vendor bills where in now they are able to use the three way matching which includes purchase order, receipts, and bills so now their finance team with easy steps can easily cross check the data without manual intervention.

The foremost thing to mention is the training part which almost took less than two weeks and the best part is that their staff adapted due to the new system due to Odoo’s UI being intuitive.

Let’s See the End Results Achieved

After the implementation and within the first three months their results were measurable –

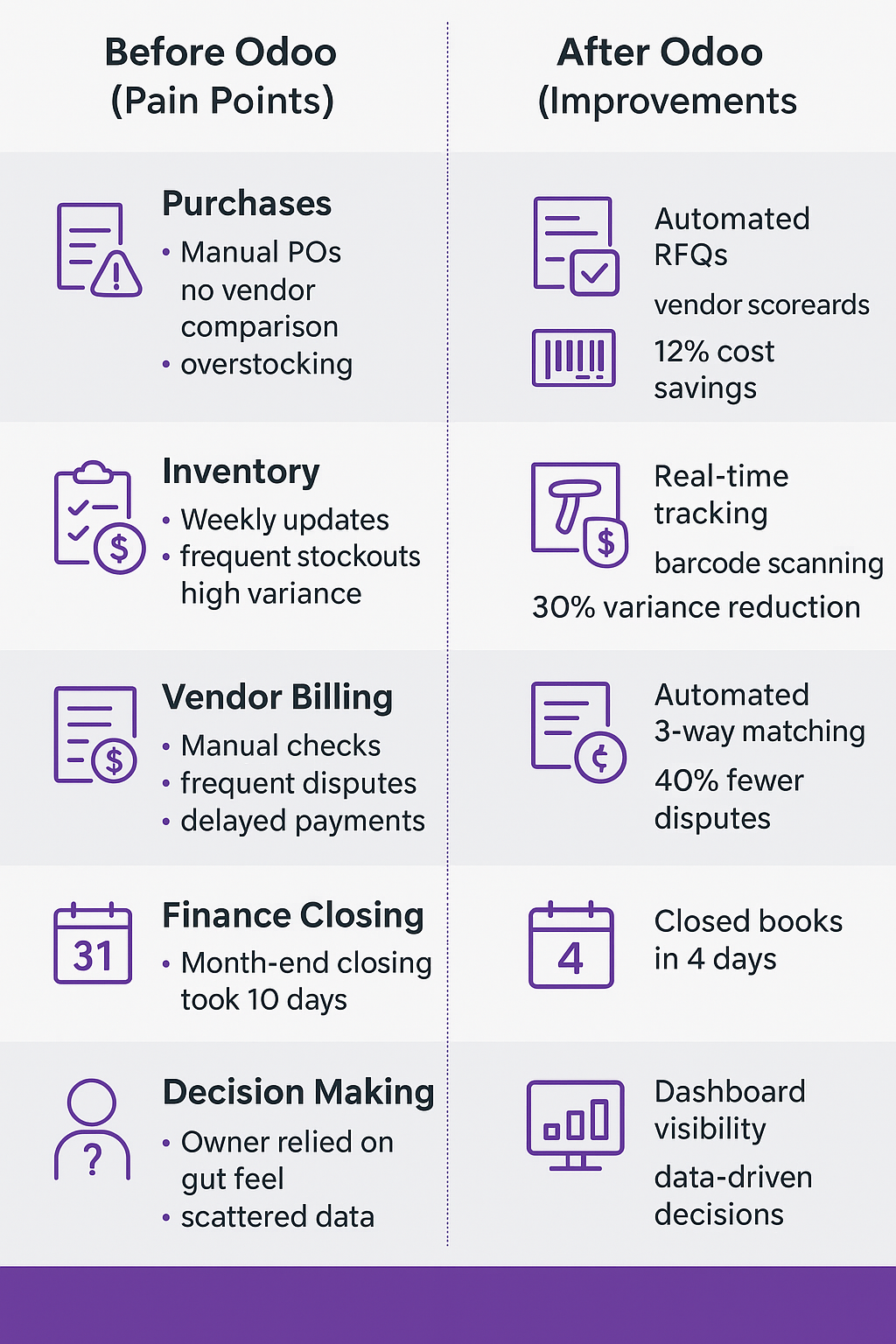

After they used the vendor comparisons they saw a 12% reduction in the purchase cost for the raw materials. Using the real time stock tracking for the inventory variance there was a drop by 30%. Having the automated bill matching option at hand now there were 40% fewer vendor disputes. Their finance team is able to do a faster month end closing dropping from ten days to 4 days. Now due to the fact they have better payment terms vendor trust has improved overall.

All in all the most important thing for the outcome in results was that this SME manufacturer has now a real time visibility to his dashboard for purchase, stock levels, and pending bills and that too in one place so no more running back and forth.

Below i have have added area, before Odoo and after Odoo improvements for a better understanding from the outcomes.

To conclude i would say that my overall experience with the plastic injection molding manufacturer has given us a success pathway where in we can start with essential modules like purchase, inventory and billing.

We should always have a real time track that will allow us to avoid both the overstocking and stockouts, and always make sure to pay your vendors on time as this will eventually help you to have negotiation power.

So, for SMEs who are plastic injection molding manufacturer, Odoo can bring you a great offering where you get a budget-friendly, practical, and proven ERP system. I have already implemented it to around 200 clients and seen their transformation without the need of investing in heavy budget ERP software.

Lastly, if you are still struggling with your injection molding manufacturing operations which include purchase control, inventory variance, or billing errors, then for sure Odoo is worth it.

To know more, just drop us a line whenever you find it feasible at sales@apagen.com or call us on +91 9971800665.

No Comments

Sorry, the comment form is closed at this time.